Our Terms & Conditions | Our Privacy Policy

Capital intensity & workforce gaps, ETManufacturing

The median capital to labour ratio across all industries in India is 6. Over the last decade, India has started to emphasize on self-reliance in manufacturing, and provide a pathway for manufacturing-led growth. The ‘Make in India’ regime has pushed for policies such as the Production Linked Incentive Schemes (PLI). The manufacturing sector is broadly classified into the formal and informal sector.

The formal manufacturing sector comprises of firms that are registered under The Factories Act, 1948, and The Bidi and Cigar Workers Act, 1966. The Annual Survey of Industries (ASI) is an annual survey that captures the health and progress of the formal manufacturing sector in India. It provides a comprehensive understanding of the manufacturing sector in India covering an estimated 2,53,334 factories in 2023 across the country.

The survey was started in the year 1959, with the latest round being 2022-23. This survey is conducted by the Ministry of Statistics and Programme Implementation (MoSPI). In 2022-23, the formal manufacturing sector today employed around 18.4 million, increasing from 16.2 million in 2018-19.

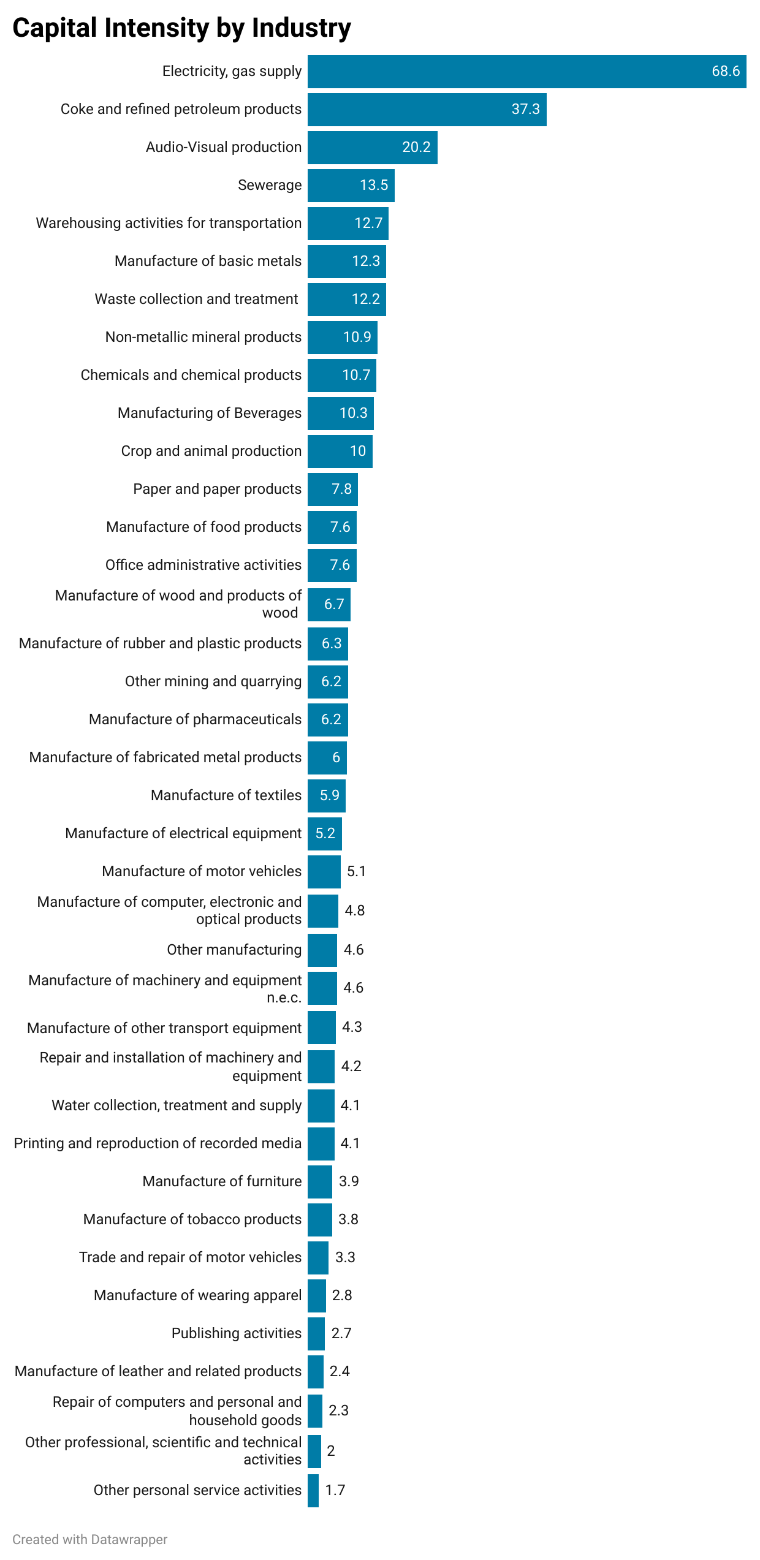

Industries are generally classified as either labour intensive or capital intensive. Capital intensive industries are defined as industries that invest a larger proportion of their expenditure on capital infrastructure than labour. To measure capital intensity within the formal manufacturing sector, we compute the ratio of value of capital infrastructure to the value of labour. This is also defined as the capital to labour ratio.

The median capital to labour ratio across all industries in India is 6. This implies that on an average, the value of the capital infrastructure is six times that of labour cost. We define industries as capital intensive, if the capital to labour ratio is higher than the median. On the contrary, industries are termed as labour intensive if the capital to labour ratio is lower than the median.

Figure 1 illustrates the capital intensity of all industries within the manufacturing sector in India. We see that supply of electricity, gas and steam, manufacture of coke and refined petroleum products and the production of motion pictures, videos and television programs are the most capital-intensive industries. Conversely the most labor-intensive firms are engaged in the repair of computers, professional scientific and technical activities, and manufacture of leather and related products.

Capital intensive industries surpass labour intensive industries on productivity and profits.

The 2022-23 round of the ASI shows that industries that were more capital intensive were associated with having a greater productivity (productivity is defined as gross value added per person engaged). While the median worker productivity across all industries was approximately INR 1 million, capital intensive industries recorded a 30% higher per worker productivity, compared to the labor-intensive industries. The analysis from the survey data also revealed that the profits for capital intensive firms was 2.5 times that of labor-intensive industries, with the average profit across all industries being approximately INR 15,000 crore.

Gender wage gap exists; however, it is lower for capital intensive industries

With respect to the gender wage gap, men earn 35% higher than women, on average, across all industries. The wage gap is marginally lower for capital intensive firms (30%), compared to labour intensive firms (40%). However, the wage gap across workers between the two groups was minimal. This indicates that the wage rate between both type of industries (capital and labor intensive) is the same. While, the overall wage differential was negligible between the two types of industries, the top-five capital intensive industries paid their workers around 40% higher than the top-five labour intensive ones. This means that capital intensive firms were not only generating more output and profit, but were also paying their workers more equitably.

Contractual workforce dominates, female representation lags

The push for manufacturing however, also requires a skilled workforce to support it, but the poor state of vocational and technical training for women is reflected in their lower share in employment in the capital-intensive sector. Women make up 18.4% of the total full time employed labour force in the formal manufacturing sector in India. However, this share is relatively smaller on average for capital intensive industries (11%), compared to labour intensive industries (17%). In an attempt to cut costs, capital intensive industries have tried to downsize their full-time workforce.

The manufacturing sector of India today is marked by a high contractual workforce, characterized by high job insecurity, leaving them with little or no social security benefits. In the capital-intensive industries, the contractual workforce as a share of the total workforce stood at 40% on average, compared to 28% in the labour-intensive industries. Therefore, in essence, capital-intensive industries are marked by a lower share of female participation, but a higher contractual workforce.

While increased capital intensive industries has numerous benefits in terms of firm and worker productivity, the long-term sustainability of a myopic focus on capital investment is questionable, as it holds back female employment, and also engages a disconcerting share of contractual workers. This approach may well deliver on our growth targets, but without a more holistic approach, we risk sweeping some concerning facts under the rug with promising headline figures.

The capital-intensive industry contributes to almost 64% of total gross value added in the manufacturing sector, employing close to 50% of the total workforce in the sector. Given this, the focus should now be on improving the composition of the workforce in these industries, given their lower share of female workers and high share of contractual workers.

Since capital intensive industries require a more skilled workforce, importance should be given to vocational training and skill development programs tailored to these industries, with a greater emphasis on improving female employment outcomes, as they are more likely to get paid equally here than in labour intensive industries. These upskilling initiatives will also provide confidence to firms to make long-term commitments to their workers, improving job security, morale and consequently productivity, and lowering attrition.

India’s manufacturing surge, led by capital-intensive industries, signals promising economic gains—but also exposes critical gaps in workforce equity and stability. To ensure long-term, inclusive growth, policies must go beyond capital investment and prioritize skill development, gender inclusion, and job security. A resilient manufacturing future depends not just on machines, but on empowering the people who run them.

- Published On Aug 18, 2025 at 08:41 AM IST

Join the community of 2M+ industry professionals.

Subscribe to Newsletter to get latest insights & analysis in your inbox.

Get updates on your preferred social platform

Follow us for the latest news, insider access to events and more.

Images are for reference only.Images and contents gathered automatic from google or 3rd party sources.All rights on the images and contents are with their legal original owners.

Comments are closed.