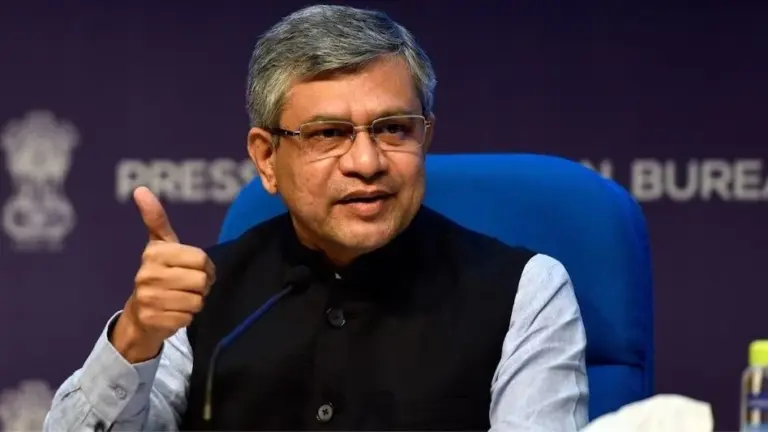

In a significant move to strengthen India’s electronics manufacturing ecosystem, the government has approved seven projects under the Electronics Components Manufacturing Scheme (ECMS) out of the 249 proposals received, Union Electronics and IT Minister Ashwini Vaishnaw announced on October 27.

“These projects mark a strategic beginning for India’s journey toward design-led, self-reliant electronics manufacturing,” Vaishnaw said, adding that the first batch includes proposals for manufacturing printed circuit boards (PCBs), camera modules, copper laminates, and polypropylene films — all critical inputs for the electronics value chain.

According to Electronics and IT Secretary S Krishnan, the approved projects represent a cumulative investment of ₹5,532 crore, with the potential to generate 5,195 direct jobs.

Among the approved firms, Kaynes Circuits has secured four projects covering PCBs, HDI boards, camera modules, and laminates. SRF Ltd will establish a plant to produce polypropylene film, a key material in capacitors, while Syrma Strategic Electronics and Ascent Circuits will manufacture multi-layer PCBs used across sectors from consumer electronics to aerospace and defence.

Vaishnaw emphasised that the projects are expected to reduce India’s electronics import bill by ₹18,000–20,000 crore annually, while enabling domestic value addition of up to 40 percent — on par with China’s current levels.

“Once these plants are operational, India will not only manufacture finished products but also their core components — a vital shift for long-term competitiveness,” he added.

Of the seven approved projects, five are located in Tamil Nadu, while Andhra Pradesh and Madhya Pradesh each host one unit. Officials noted that this geographic spread reinforces balanced regional growth and the expansion of high-tech manufacturing beyond metros.

The ECMS, which closed its first phase on September 30, 2025, has received an overwhelming ₹1.15 lakh crore worth of investment proposals, translating into ₹10.34 lakh crore in projected production and over 1.42 lakh jobs. The capital equipment window under the scheme remains open.

Future approvals will continue on a first-come, first-served basis, with multiple batches expected before the scheme’s current phase ends in 2027.

The ECMS is also paving the way for India’s first-ever Copper Clad Laminate (CCL) manufacturing facility — a critical base material used in multi-layer PCBs, which are currently imported. Additionally, the production of polypropylene films — key components in capacitors — will now take place domestically, serving industries such as consumer electronics, automotive, telecommunications, and industrial manufacturing.

“These breakthroughs mark India’s strong entry into component materials manufacturing — an area that has long remained dependent on imports,” Vaishnaw said.

What is ECMS

Launched in March 2025, the Electronics Component Manufacturing Scheme (ECMS) aims to boost India’s electronics component ecosystem through differentiated fiscal incentives — turnover-linked, capex-linked, and hybrid — depending on the nature of investment. The goal is to enhance domestic value addition, integrate Indian firms into global supply chains, and establish a sustainable base for critical components such as display modules, camera modules, and printed circuit board assemblies.

With the first approvals now cleared, India’s ambition of becoming a global electronics manufacturing hub is taking a decisive step closer to reality.

Images are for reference only.Images and contents gathered automatic from google or 3rd party sources.All rights on the images and contents are with their legal original owners.