Our Terms & Conditions | Our Privacy Policy

Can NoPo Put India On The Global Nanotechnology Map?

The world has long looked at nanotechnology with scepticism. This is because the field involves manipulating matter at the atomic level to create entirely new materials or products.

In the International System of Units, nano refers to one billionth of a metre. For context, a human hair strand is about 80K-1 Lakh nanometres wide, and nanotechnology operates at sizes lower than 100 nanometers.

However, as mind-boggling as it sounds, the potential of nanotechnology is massive — from transforming medical treatments and electronics (batteries, semiconductor chips, or even rockets) to revolutionising energy production and advancing environmental sustainability.

More than a decade ago, when scepticism regarding this technology was at its peak. An undeterred Gadhadar Reddy, a native of Bengaluru, dreamt of working on carbon nanotubes (CNTs).

His inspiration? Dr Richard Smalley, who received a Nobel Prize in 1996 for his work on fullerenes, and Japan’s Sumio Iijima, who discovered CNTs in 1991. While this was a great scientific feat, scaling this tech commercially was a challenge back then.

Reddy grew up with a passion for nanotechnology, and its potential applications in space deeply influenced his own journey.

It is because of this conditioning that Reddy decided to disrupt this world by picking up the toughest of all tasks — develop commercially viable CNTs.

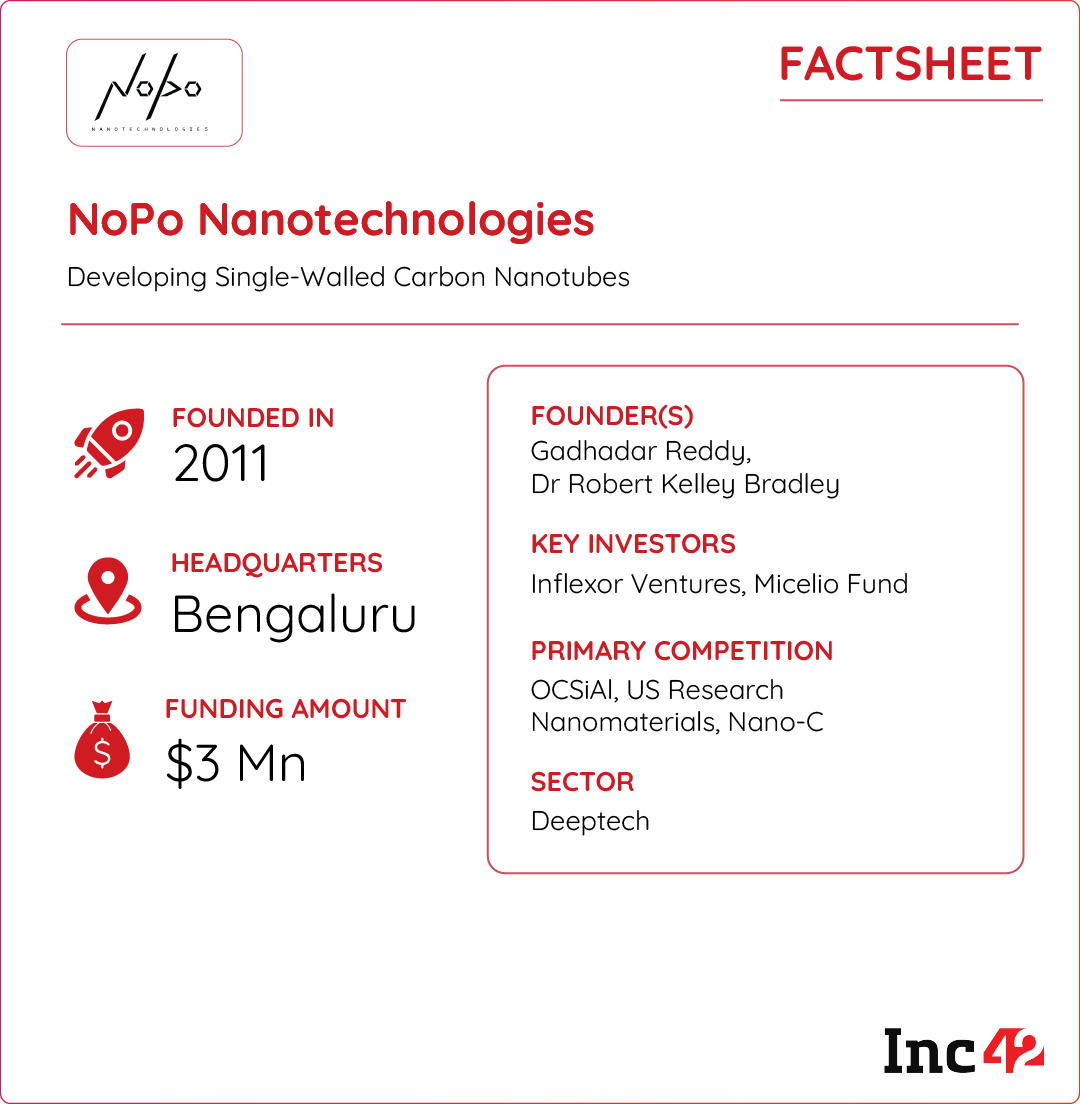

To realise his dream, he pursued his master’s degree in nanotechnology from Louisiana Tech University in the US. After returning to India in 2011, he founded NoPo Nanotechnologies, along with scientist Robert Kelley Bradley.

Today, the founder claims that NoPo is the only Indian startup developing single-walled carbon nanotubes (SW CNT) in-house.

After almost 13 years of intensive R&D, crores of capital infusion, and building reactors from scratch, NoPo specialises in driving innovation in the areas of lithium-ion batteries, semiconductors and space technology.

Reddy claims that today NoPo has emerged as a promising force in India’s deeptech landscape, as its material science innovation holds the potential to transform many industries.

The Making Of NoPo — A Decade Long Expedition

Reddy has been a space enthusiast ever since he was a kid. During a summer camp, he got an opportunity to meet Rakesh Sharma, an Indian cosmonaut.

While interacting with Sharma, Reddy realised that even though space exploration was poised to advance, it involved major risks.

Even today, one in every 100 rockets has a risk of an explosion due to limitations in material science. This was the instance that first drove Reddy’s curiosity in this field.

After Smalley won the Nobel Prize, Reddy saw that the material science fraternity became more eager about nanotubes.

This piqued his interest, too, and he got involved in the creation of a nanotech club at BMS College of Engineering in Bengaluru.

During this time, he found that almost all the technological know-how in India was limited to textbooks and college labs. The gap in India’s technology building story and heavy reliance on imports bothered him.

Thus, he went to the US to gain more knowledge and experience in the field of nanotechnology, where he learnt the different methods of making CNTs.

In this process, he figured out that while commercial attempts were made in producing nanotubes in batches, no one was working on a continuous production process.

“Producing nanotubes in a continuous process was more challenging, but that made more sense commercially,” Reddy said.

While researching, Reddy said, he came across Smalley’s high-pressure carbon monoxide (HiPCO) method, which had ample research credibility among the scientific fraternity.

He partnered with Bradley, who had co-invented HiPCO along with Dr Smalley at Rice University in the US. Reddy came back to India and set up NoPo.

The HiPCO method involves a reactor, inside which carbon monoxide is used with metal carbonyls as a catalyst. At high temperatures of about 1000°C and high pressures of 100 atmospheres, the catalyst and gas together produce the single-walled CNT.

span {

margin: 0;

padding: 3px 8px !important;

font-size: 10px !important;

line-height: 20px !important;

border-radius: 4px !important;

font-weight: 400 !important;

font-style: normal;

font-family: noto sans, sans-serif;

color: #fff;

letter-spacing: 0 !important;

}

.code-block.code-block-55 .tagged {

margin: -4px 0 1px;

padding: 0;

line-height: normal;

}

@media only screen and (max-width: 767px){

.code-block.code-block-55 {

padding:20px 10px;

}

.code-block.code-block-55 .recomended-title {

font-size: 16px;

line-height: 20px;

margin-bottom: 10px;

}

.code-block.code-block-55 .card-content {

padding: 10px !important;

}

.code-block.code-block-55 {

border-radius: 12px;

padding-bottom: 0;

}

.large-4.medium-4.small-6.column {

padding: 3px;

}

.code-block.code-block-55 .card-wrapper.common-card figure img {

width: 100%;

min-height: 120px !important;

max-height: 120px !important;

object-fit: cover;

}

.code-block.code-block-55 .card-wrapper .taxonomy-wrap .post-category {

padding: 0px 5px !important;

font-size: 8px !important;

height: auto !important;

line-height:15px;

}

.single .code-block.code-block-55 .entry-title.recommended-block-head a {

font-size: 10px !important;

line-height: 12px !important;

}

.code-block.code-block-55 .card-wrapper.common-card .meta-wrapper .meta .author a, .card-wrapper.common-card .meta-wrapper span {

font-size: 8px;

}

.code-block.code-block-55 .row.recomended-slider {

overflow-x: auto;

flex-wrap: nowrap;

padding-bottom: 20px

}

.code-block.code-block-55 .type-post .card-wrapper .card-content .entry-title.recommended-block-head {

line-height: 14px !important;

margin: 5px 0 10px !important;

}

.code-block.code-block-55 .card-wrapper.common-card .meta-wrapper span {

font-size: 6px;

margin: 0;

}

.code-block.code-block-55 .large-4.medium-4.small-6.column {

max-width: 48%;

}

.code-block.code-block-55 .sponsor-tag-v2>span {

padding: 2px 5px !important;

font-size: 8px !important;

font-weight: 400;

border-radius: 4px;

font-weight: 400;

font-style: normal;

font-family: noto sans, sans-serif;

color: #fff;

letter-spacing: 0;

height: auto !important;

}

.code-block.code-block-55 .tagged {

margin: 0 0 -4px;

line-height: 22px;

padding: 0;

}

.code-block.code-block-55 a.sponsor-tag-v2 {

margin: 0;

}

}

]]]]>]]>

NoPo’s Early Hiccups

While working on this technology, the first challenge that NoPo encountered was with building reactors. Even as a few in the US had designed reactors that could work with the HiPCO method, the startup decided to design and build it in-house from scratch.

Gradually, NoPo started designing almost all the equipment in-house, including heaters, because no one in India could provide such technology. It also built the catalyst in-house and has a patent on it. This basic technology development took the company almost four years.

In 2017, NoPo took part in the ELEVATE 100 programme in Karnataka, which gave a boost to the startup to begin working on water filtration membranes using CNTs.

In the initial years, the company was completely focussed on this area. It also received a grant from the Indian Navy to build more of these membranes.

While it helped NoPo build its foundation and the startup could showcase the potential of CNT in lowering water wastage in the filtration process, Reddy and his team soon realised the need for venture capital funding, which was unlikely to come in if they only kept building membranes.

Therefore, the founder pivoted. The startup was now using the tech to produce nanotubes for batteries and electronics.

The company sustained the Covid-19 pandemic on the money it kept receiving from the naval project, but in 2022, it fully embraced the batteries and electronics segment.

During this process, the startup onboarded Arunima Patel and Anto Godwin to the team. In 2024, NoPo raised $3 Mn in seed funding from Inflexor Ventures and Micelio Fund.

CNTs In Batteries: A Match Made In Heaven

To the naked eye, CNTs appear as a jet-black, ultra-light powder. However, their significance is multi-faceted in the material world.

CNTs offer significantly higher heat resistance than materials like silicon, making them valuable for lithium-ion battery anodes, semiconductors, and other applications where thermal management, power efficiency, and durability are critical. The smaller the tubes, the greater their resistance.

While many are focussed on larger nanotubes, NoPo develops small nanotubes of 0.8-1 nanometer in diameter.

“Besides, our goal was to work towards climate action. Numerous studies show its positive impact on the environment. For example, if we add a ton of nanotubes into concrete, it reduces carbon emissions by 840 tons. Similarly, if it goes into polymers, emissions are reduced by 30%. Even batteries with nanotubes result in 20% less emissions than a battery without nanotubes,” Reddy said.

However, while NoPo is involved in large-scale production of CNTs, the startup does not sell the raw materials.

Making Commercial Sense Of NoPo’s Nanotech

NoPo has segmented its customers into three main categories — polymers, automotive batteries, and semiconductors.

In 2023, it began working with its first set of polymer customers, helping them use CNTs as additives to make plastics conductive. These conductive polymers are used in everything from OLEDs and batteries to sensors and medical devices.

Currently, NoPo is at the sampling stage with its second group of customers — the lithium-ion cell manufacturers. With the rising demand for electric vehicles and drones, the startup is already set to tap into a 220 GWh market by 2030.

Besides, the startup is also eyeing emerging chemistries like sodium-ion batteries and others.

CNTs are highly heat resistant and can be used in combination with silicon dioxide in the anode of Li-ion cells to scale their efficiency and safety. NoPo claims its CNTs can increase charge-to-discharge cycles by 10X.

The company has started R&D with its third set of customers — the chip manufacturers. CNTs are being explored for making transistors, but Reddy believes that it would take another 5-10 years for the commercial uptake in this space.

Meanwhile, its materials are also finding increasing usage in infrared (IR) sensors.

NoPo’s main lineup of products comprises the raw single-walled CNTs, the battery grade CNTs, semiconductor CNTs used for IR sensors, electronics, biomedical applications, single chiral CNTs, and metallic CNTs.

Besides, the startup has also developed its proprietary NoPo Carbonyl Detectors, a solution for the measurement of Nickel and Iron Carbonyl in the presence of carbon monoxide. Even though it’s not going to be the main source of its revenue, NoPo has kept its ship sailing by selling these detectors in the last few years.

It currently has customers in the US, Japan, and India. Depending on the use cases, purification level, and purchase orders, the price of these CNT products varies anywhere between $25 per gram and $100K per gram.

NoPo’s Nanotech Path Ahead

Though NoPo has identified its target markets, this is just the beginning of its commercial journey. After 13 years, NoPo clocked around INR 3 Cr in revenue in FY25.

The company did not share the projections, but its goal from here on is to scale its top line. To achieve this, the company is building the next generation of its reactors.

What once took a month or two to produce a single millilitre of CNT solution is now down to 10-14 days. Now, the company is looking to optimise the production process to make this cycle even faster.

NoPo plans to raise $10 Mn-$15 Mn in its next round within a year. With this, it aims to scale its business with customers in spacetech.

Keeping all the commercial aspects steady, NoPo is highly committed to sustainability. For instance, while procuring carbon monoxide from the market, it ensures zero emissions.

While at it, the company aims to get carbon dioxide emitted by other factories and use it in the production of CNTs. It has already put together novel methods in place to produce carbon monoxide from carbon dioxide.

The technology that NoPo is working on can turn out to be hazardous to the human body and the environment in certain conditions. However, the startup claims to have introduced high ESG standards. Its Sustainability Report 2024 suggests that even the water discharged in the process is treated before they are discharged into the municipal lines.

Currently, its employees working in the production area near the reactors have exposure to carbon monoxide within a 10 PPM (parts per million) range, which it is aiming to reduce to zero.

In terms of sustainability in the supply chain, NoPo claims that 60% of its materials (by value) are sourced locally in the city.

With an aim to innovate with the environment in focus, it will be interesting to track NoPo’s journey from here on.

[Edited by Shishir Parasher]

]]>

Images are for reference only.Images and contents gathered automatic from google or 3rd party sources.All rights on the images and contents are with their legal original owners.

Comments are closed.