Auburn University scientists have developed a new class of materials that lets researchers precisely control free electrons, a breakthrough that could reshape the future of computing and chemical manufacturing.

Their study introduces a material system that allows fine-tuned control over how electrons behave within matter, potentially paving the way for faster computers, smarter machines, and more efficient industrial processes.

Electrons form the foundation of chemistry and technology. They drive energy transfer, catalysis, and conductivity. In most materials, they remain bound to atoms, which limits flexibility.

Auburn researchers aimed to change that by creating materials where electrons can move freely through open spaces.

“By learning how to control these free electrons, we can design materials that do things nature never intended,” says Dr. Evangelos Miliordos, Associate Professor of Chemistry at Auburn and senior author of the study.

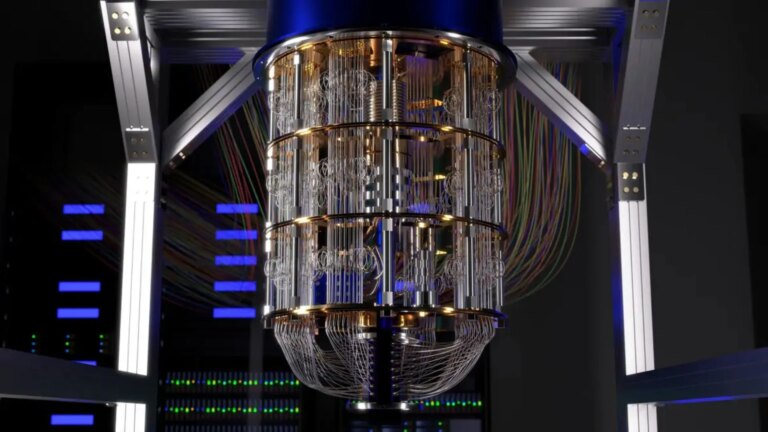

The team’s innovation focuses on Surface Immobilized Electrides, a new type of material made by attaching solvated electron precursors to stable surfaces like diamond and silicon carbide.

This design allows the material’s electronic properties to be both durable and adjustable.

By changing how the molecules are arranged, electrons can either cluster into isolated “islands” that act like quantum bits or spread into wide metallic “seas” that power chemical reactions.

From quantum computing to catalysis

This versatility opens up possibilities across several industries.

One arrangement could support powerful quantum computers capable of solving problems beyond the reach of today’s machines.

Another could lead to better catalysts that speed up reactions in the production of fuels, medicines, and materials.

“As our society pushes the limits of current technology, the demand for new kinds of materials is exploding,” says Dr. Marcelo Kuroda, Associate Professor of Physics at Auburn.

“Our work shows a new path to materials that offer both opportunities for fundamental investigations on interactions in matter as well as practical applications.”

The ability to guide electrons at will could connect advances in quantum science and chemical engineering, creating a shared platform for future innovations.

Toward real-world applications

Earlier types of electrides were unstable and difficult to reproduce. The Auburn team solved this problem by depositing their materials directly onto solid surfaces, which improved both stability and scalability.

This development could enable commercial applications in electronics, sensors, and advanced catalysts.

“This is fundamental science, but it has very real implications,” says Dr. Konstantin Klyukin, Assistant Professor of Materials Engineering at Auburn.

“We’re talking about technologies that could change the way we compute and the way we manufacture.”

The project brought together researchers in chemistry, physics, and materials engineering. Miliordos says this collaboration is only the start.

“By learning how to tame free electrons, we can imagine a future with faster computers, smarter machines, and new technologies we haven’t even dreamed of yet,” he says.

Auburn’s research marks a promising step toward materials that not only expand scientific understanding but also bridge the gap between theory and real-world technology.

The study is published in the journal ACS Materials Letters.

Images are for reference only.Images and contents gathered automatic from google or 3rd party sources.All rights on the images and contents are with their legal original owners.