Our Terms & Conditions | Our Privacy Policy

How the Architectural Model Maker Behind the Chinese Pavilion at the Venice Biennale Impressed Architects Around the World | Features

Model of Fenix Museum of Migration, scale 1:100. Image credit: MAD

In recent years, the global architecture industry has been challenged by disruptions such as the pandemic and deglobalization, while also undergoing transformation with the emergence of technologies like AI, 3D printing, and automated construction. QZY faces these changes alongside architects, continually exploring and experimenting to find solutions — bringing its own unique perspective to the future of global model-making services.

Urban design by Foster + Partners, scale 1:500. Image credit: QZY Models

Collaborative

Experiments at the Venice Biennale

This

year at the Venice Biennale, QZY Models was entrusted with producing

the complete set of architectural models for the China Pavilion. On a

stage that champions experimentation and provocation, model-making

extends far beyond execution — it becomes a co-creative process

with architects. Each model serves as a distinct investigation into

architectural thought and spatial expression.

Plug-in

Update City

production process. Video credit: QZY Models

One

of the most compelling works was Plug-in

Update City,

a collaboration between PAO (People’s Architecture Office) and

Long Ying Research Group of Tsinghua University. The architects

envisioned a conceptual installation built from salvaged components

of old models, combined with newly 3D-printed green “plug-ins” to

explore ideas of micro-urban renewal. In close coordination with QZY, the team collected, standardized, and integrated hundreds of

discarded model parts within just two weeks. The process was highly

synchronized: While the architects designed on-site at their workshop, one team constructed the road network base, another gathered

model fragments, and a third fabricated the 3D-printed elements.

To

balance sustainability and performance, the team used biodegradable

green PLA (Polylactic Acid) for the 3D-printed components and applied

rigorous pre-drying procedures to ensure material stability. The

final model measured 6 x 4.5 meters. For overseas transport, the base

was modularized along original patchwork, such as roads and rivers,

minimizing visible seams while ensuring structural integrity during

shipment.

12 Rhythms in Liangzhu. Image credit: QZY Models

Another

piece, 12

Rhythms in Liangzhu

by the China Academy of Art, explored the connection between sound

and nature. QZY developed a custom model that incorporated

multimedia equipment, musical instruments, and projection systems.

The main challenge was achieving a floating display that seamlessly

integrated tablets and physical components. They engineered a

standardized interface for electronics, lighting, and later additions

by the creators.

In

City

in China – Nature of All Things

by WAY studio and Tencent Research Institute, QZY fabricated a

nearly three-meter-tall model integrating moss ecosystems, lighting,

misting, and water circulation systems. Suspended via fine steel

wires, the model demanded exceptional strength and airtightness. The

model employed a PETG 3D-printed structure reinforced with steel, its

untreated surfaces promoting moss growth. Structural connections were

reinforced with steel rivets, balancing strength with modular

assembly needs.

Nature

of All Things

production process. Video credit: QZY Models

Do

We Still Need Professional Model Studios in the Era of 3D Printing?

With

3D printing becoming increasingly accessible, many architects now have their own 3D printers for daily use. So, where does that leave

professional model studios?

“Back

in the early 1990s, models in China were predominantly handmade,”

recalls Richie Ren, founder of QZY Models. “Then came laser

cutting, CNC, and 3D printing. I’ve witnessed this evolution

firsthand, but I’ve never felt that these technologies threaten our

craft. On the contrary, especially with 3D printing, our precision

and efficiency have increased exponentially. We now tackle geometries

once thought impossible, freeing model engineers from repetitive

tasks and unlocking new creative possibilities alongside

collaborating architects.”

Harbin Opera House model, remade by QZY Models based on a damaged original, scale 1:150. Image credit: MAD

QZY’s collaborations with MAD frequently incorporate 3D printing.

For instance, the Fenix Museum of Migration and Lucas Arts Centre

would have been nearly impossible to produce without it. But printing

is only the beginning.

For

the Fenix Museum model, MAD sought a realistic material

representation: metal and wood on the viewing platform, concrete and

brick on the former factory. The “tornado” structure on the

observation deck was especially complex, requiring a split assembly

strategy at its junction with the old warehouse. Its final aluminum

finish was achieved through meticulous polishing and electroplating,

while the wooden underside was recreated through hand-painted

detailing. The aged brick walls combined UV printing with manual

colorwork to achieve an authentic weathered appearance.

Fenix

Museum model

production process. Video credit: QZY Models

Secondary

Design for Better Visual Realism

When observing architectural scale models, the viewer does not shrink alongside the model — resulting in perceptual distortions where certain details recede while others become exaggerated. Consider structural beams measuring 5 cm vs. 3 cm in reality: At a 1:100 scale, the 0.5 mm and 0.3 mm representations become optically indistinguishable. To counter this, our studio deliberately amplified the differential to 0.6 mm versus 0.3 mm, or beyond.

To preserve visual clarity, model designers intentionally exaggerate key elements by adjusting thickness, texture, or color saturation, ensuring the design intent remains legible and impactful at scale. To support this, QZY has developed a systematic calibration protocol.

On the Suzhou Hengli Tower model for Foster + Partners, tailoring proportions, material finishes, and color treatments based on how the model would be viewed. This method ensures that the core architectural narrative is not lost but enhanced through the model.

Suzhou Hengli Tower section model, scale 1:30 & 1:50. Image credit: QZY Models

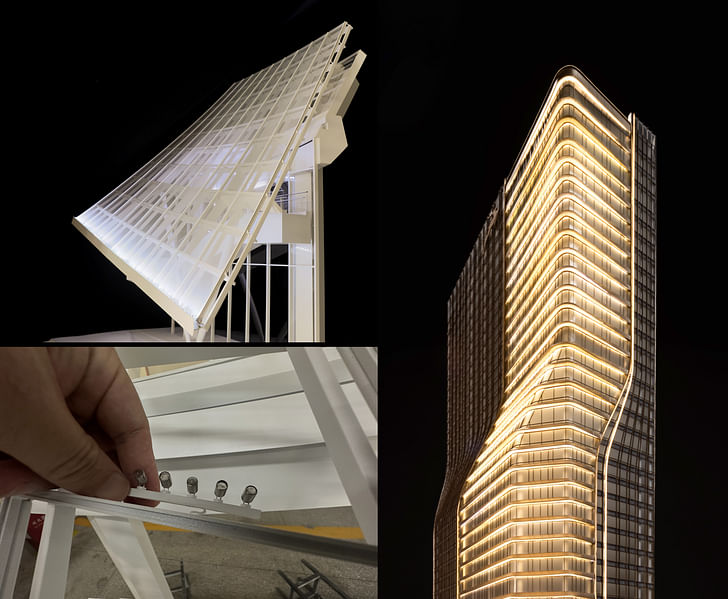

Material

constraints also influence design. For example, making tiny

spotlights under 4 mm is possible at 1:50 scale (as done for the Yiwu

Grand Theater), but not at 1:150. In a UNStudio project, a decorative

strip was originally lit with spotlights in real life. For the scaled

model, QZY Models redesigned the lighting logic: making the receiving

surface glow, effectively hiding the light source while preserving

the spatial quality.

Model-making

demands secondary design — translating form, light, and texture

into miniature sensory experiences.

Lighting strategies in two models: Yiwu Grand Theater model (1:15) VS UNS tower model (1:150). Image credit: QZY Models

Model-Making

as the Art of Substitution

In

Chinese, the word for “model” implies using something simpler to

represent something more complex — hence the idea that model-making

is the art of substitution. When architects begin a model, they tend

to replicate real materials to convey texture and materiality. QZY approaches this process through deep collaboration with the

architect, seeking to understand the design intent while balancing

factors such as feasibility and cost-effectiveness to offer informed

recommendations and deliver the best possible result.

Take,

for instance, the renovation project model for PAO. To capture the

worn character of its concrete walls, the team applied layered

surface treatments and hand-finishing techniques. While they have the capability to work with authentic materials like solid wood

or metal — as in several high-rise models for KPF’s new

headquarters — the team always prioritizes early-stage dialogue. By

aligning with the project’s ultimate goals from the outset, they help identify the most effective and elegant solutions.

Artificially simulated material (PAO renovation project model) vs. Solid wood material (KPF Highrise tower model). Image credit: QZY Models & KPF

Toward

a Global Model-Making Service

Traditionally,

architectural model-making was a localized craft. Architects would

commission nearby workshops and deliver models directly to clients.

However, as expectations for model quality have risen, local vendors

often fall short. With globalization and improved logistics, Chinese

firms — including QZY Models — have tapped into new

opportunities, offering high-quality model-making services on a

global scale. Even during the pandemic, they saw its international business grow rather than decline, thanks to its robust

logistics services and packaging capabilities.

Dubai Dar Al Arkan DaVinci Tower by Pagani, scale 1:100. Image credit: QZY Models

The

Middle East, now a hub for architectural innovation, demands top-tier

global services — including model-making. Richi Ren, founder of QZY

Models, previously worked at a model office in Dubai from 2006 to

2009. After returning to China, he remained active in the region and

later established liaison offices in the Middle East and Europe.

Based

in Shenzhen — an epicenter of design innovation — QZY collaborates with leading firms such as KPF, MAD, Foster + Partners,

Morphosis, NBBJ, RMJM, AECOM, Nikken Sekkei, and AEDAS, contributing to projects worldwide.

Changi Airport Terminal 5, scale 1:500. Image credit: QZY Models

Global

service requires close collaboration and foresight. For the recent

Changi Airport Terminal 5 model for KPF, QZY completed the

model three weeks ahead of schedule, allowing the team to switch from

air to sea freight and significantly reduce costs. The model,

measuring 7.2 x 2.5 meters, had to be displayed at both the

fourth-floor project office and the ground-floor ground-breaking site

— a logistical challenge, as it couldn’t fit in any elevator.

To

address this, the technical team deployed a four-person logistics team ten

days in advance to plan routes, navigate access limitations, and

ensure flawless presentation during the ceremony attended by national

leaders.

Beyond

large-scale models, they also developed reusable shipping

crates and even portable exhibition-ready mini-models that comply

with airline luggage restrictions. These kits feature integrated

lighting and kinetic systems, intuitive power and interface designs,

and tutorial videos to help clients set them up easily on-site.

Redefining Heritage Model Portability

Our 1:185 scale traveling model of London’s OWO redevelopment fits into 2 airline-approved cases, ready for global exhibitions.

Why it’s revolutionary:

Under 32kg/case – No excess baggage fees

Plug & play power – Type-C or power bank operated

Effortless installation – Detachable plinth, no wiring

Perfect for developers, hotels & heritage displays. Tag a project that needs this portable luxury!

Inquire: [email protected]

Explore: qzymodels.com

#QZYModels #OWO #RafflesLondon #ArchitectureModel #TravelingModel #PortableDesign #HeritageArchitecture #ModelMaking #EPRArchitects #WestminsterDevelopment #LuxuryDesign #ScaleModel

Posted by QZY Models on Monday, July 14, 2025

Traveling

model of London’s OWO redevelopment. Video credit: QZY Models

From

speculative installations at the Venice Biennale to the mirrored

curves of the Fenix Museum, from KPF’s solid wood model in Manhattan

to the cross-border logistics of Changi T5 — QZY consistently rises to the challenges of design articulation,

fabrication precision, and global delivery.

QZY

Models’ core value lies not in manufacturing alone but in acting

as a co-creator and technical partner for architects. Through deep

understanding and technical fluency, they build enduring

partnerships — bridging vision and realization, detail and

ambition.

Images are for reference only.Images and contents gathered automatic from google or 3rd party sources.All rights on the images and contents are with their legal original owners.

Comments are closed.